Yep. These were a stopgap in the days when normal users could not be expected to have a functional home network of any sort. Those were indeed active devices, and had a lump in the middle of the cable that basically amounted to an integrated USB hub.

They didn't catch on because in the era they existed it was very difficult to achieve any kind of connectivity with them to the outside world. By the time that was able to be ubiquitous, smartphones were already happening.

all the work

You have, like, seen my post history, right?

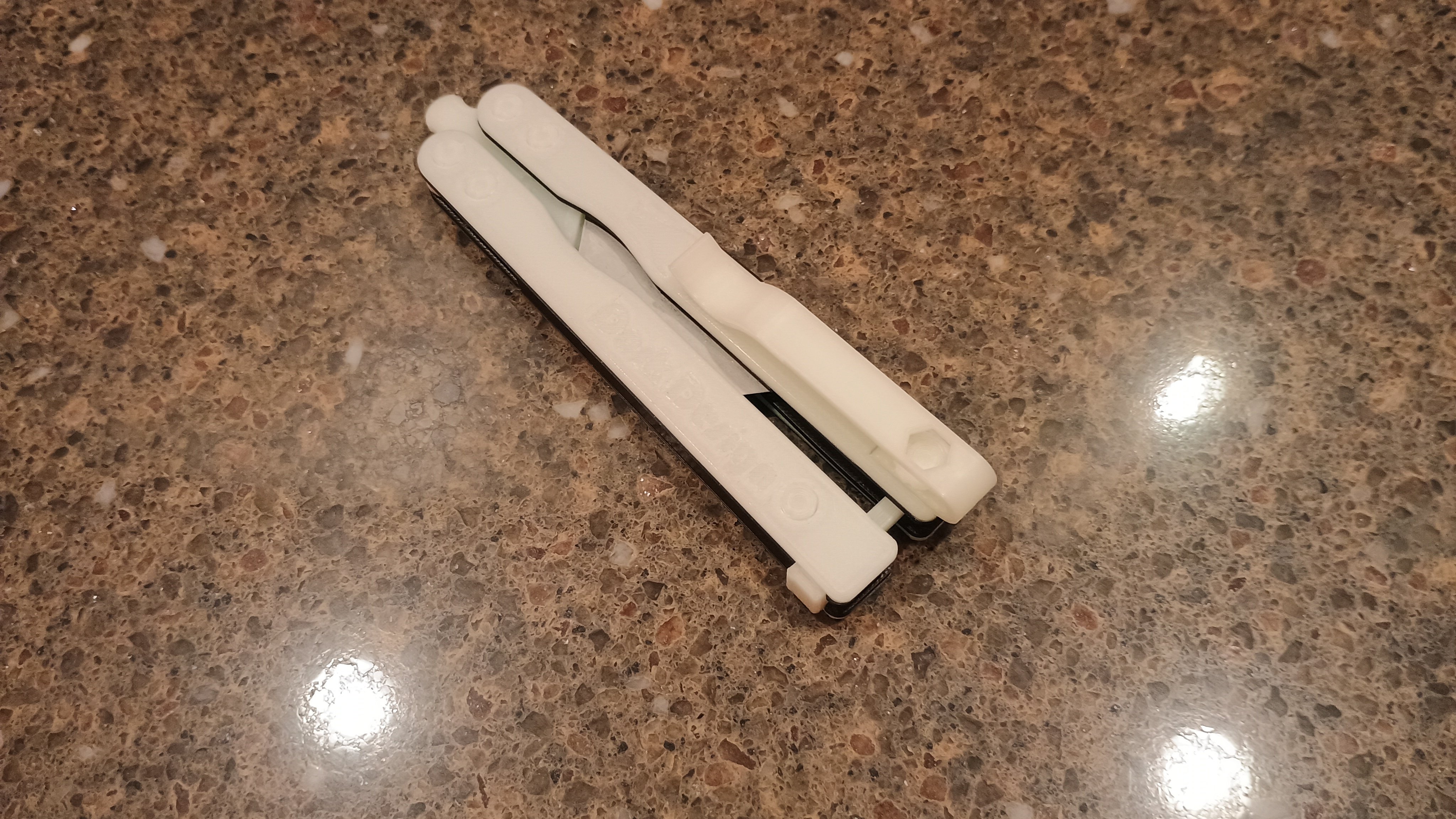

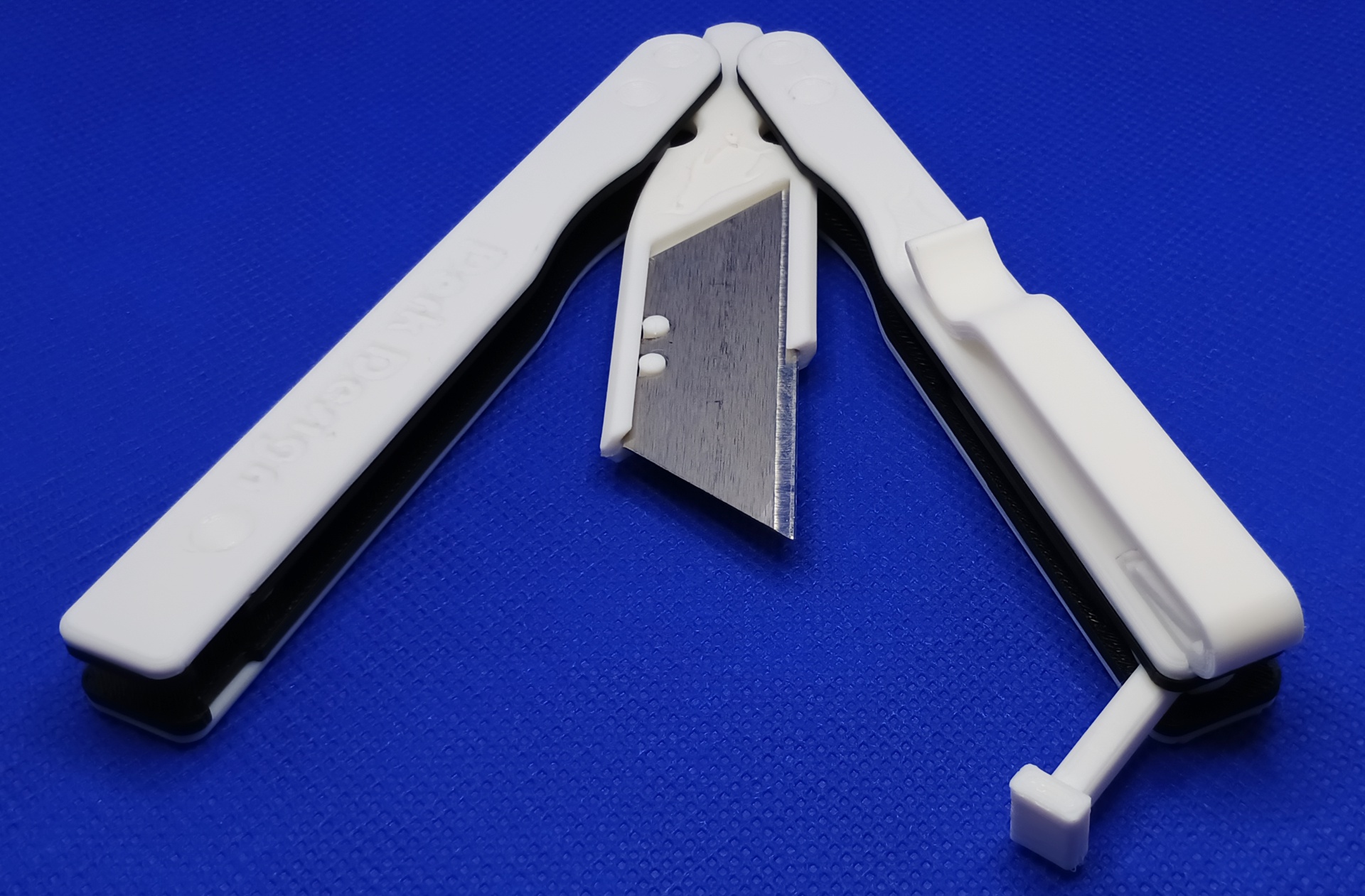

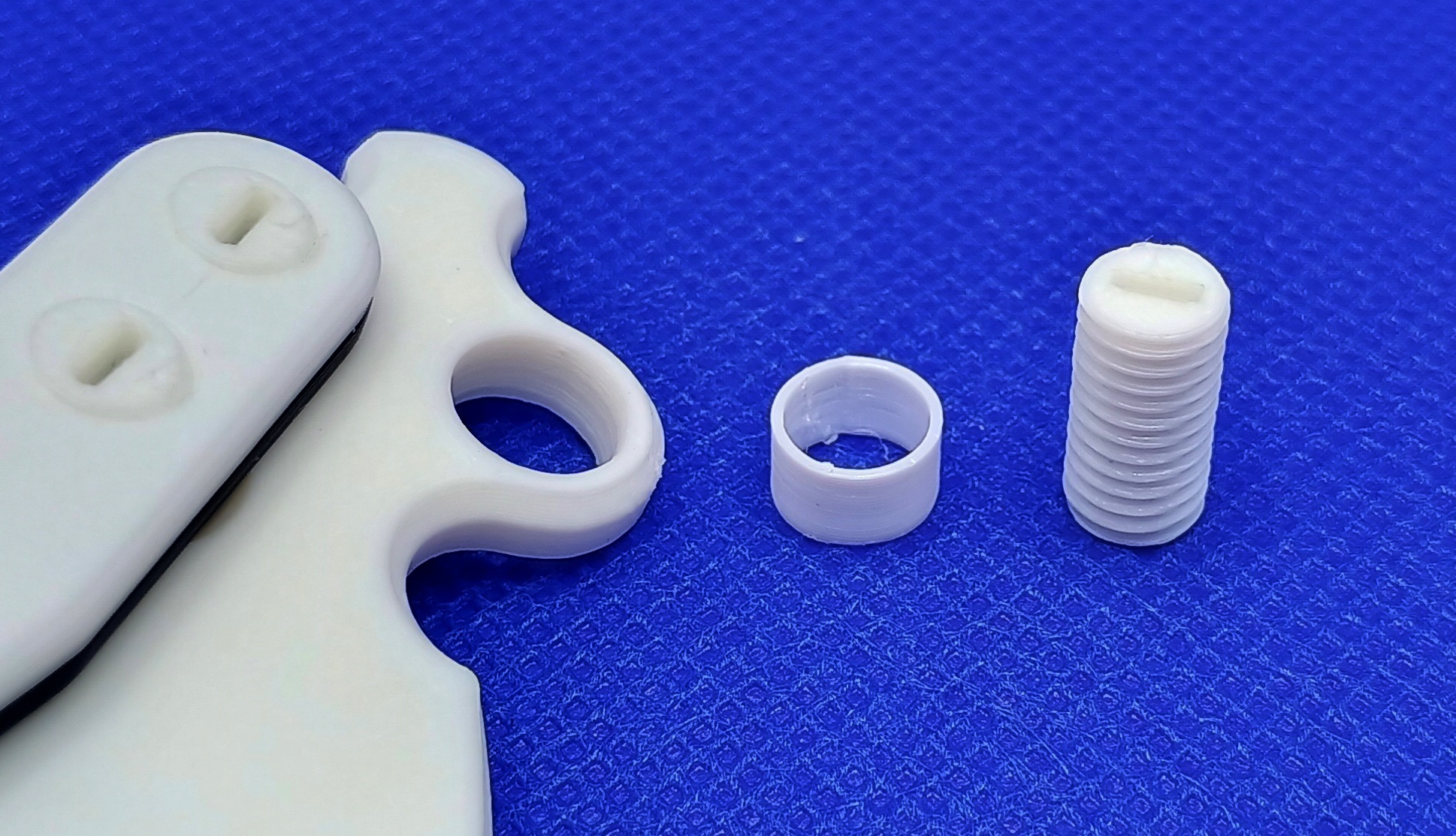

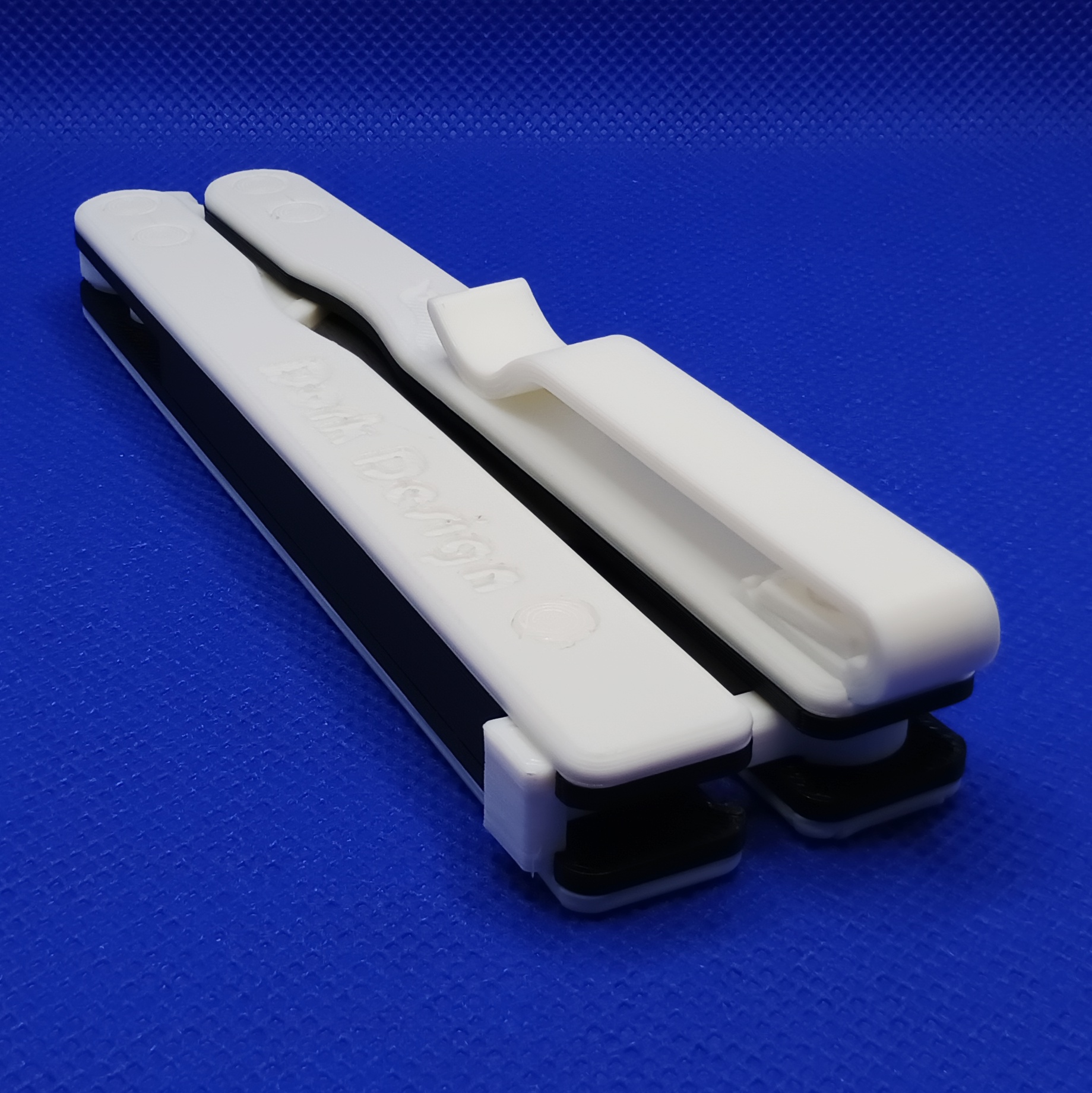

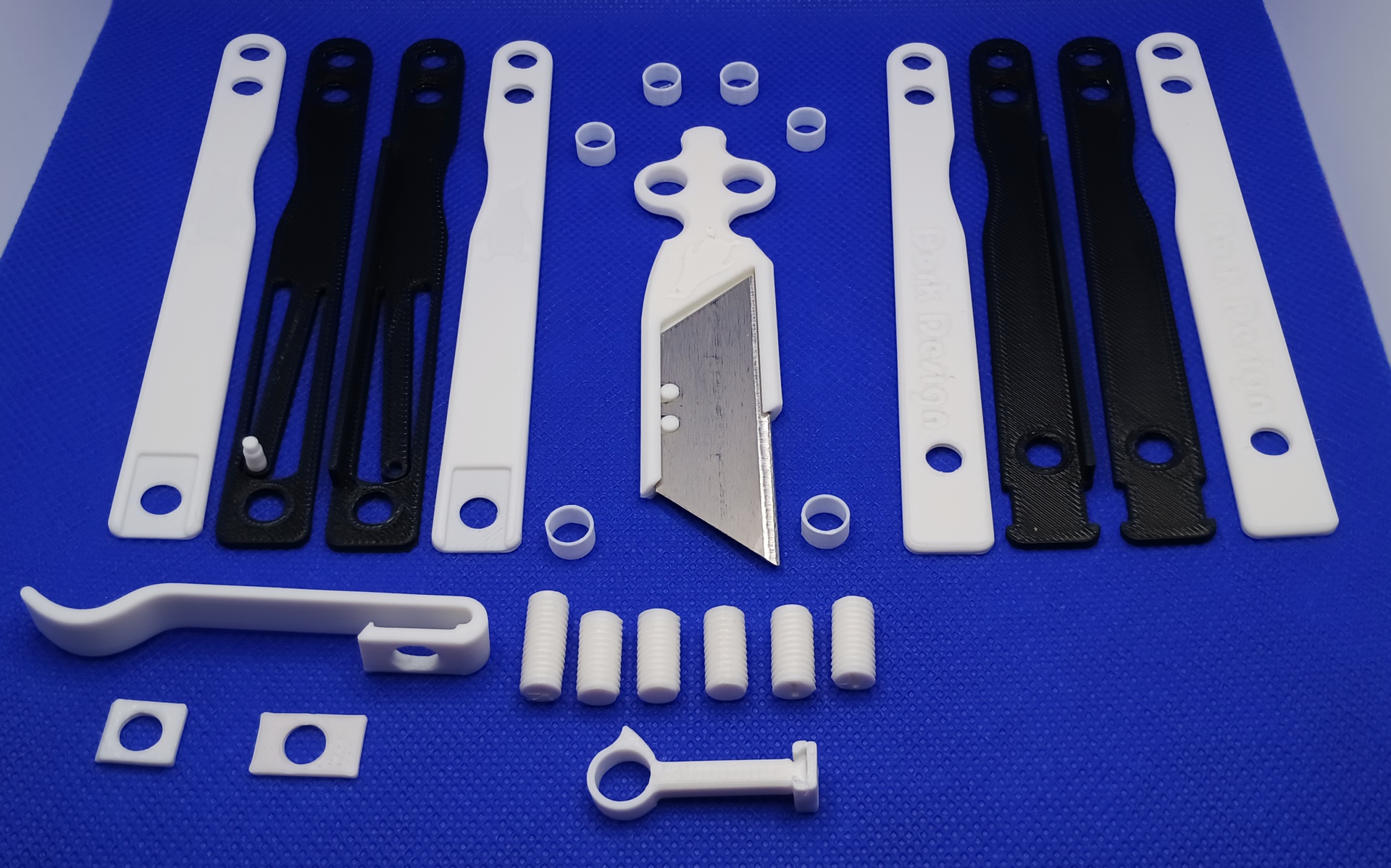

Here is the current spread. Not everything I have, just what's hooked up at the moment. Never mind the crap lighting in here.

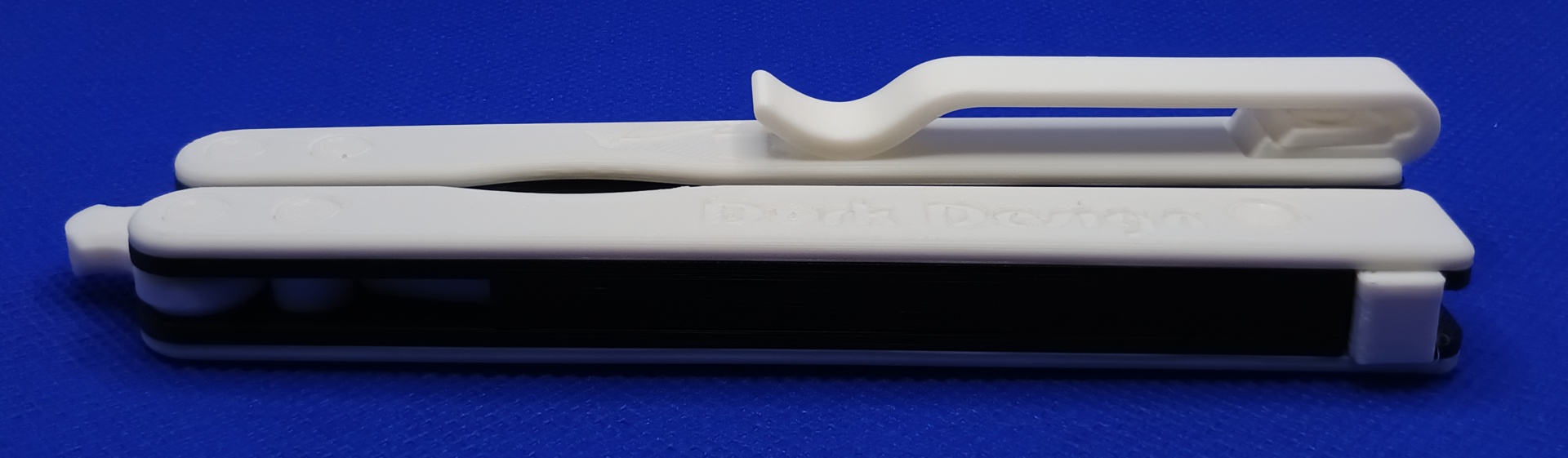

The machine in question.

It's slightly less absurd than that, I guess, because modern smartphones do at least still have telephone functionality.

Plenty of kids I grew up with also called Nintendo and Atari cartridges "tapes." It made sense from an ergonomic standpoint and from the point of view of someone who had no interest in understanding what was actually going on inside the machine. It's a rectangular plastic thing you put in the machine to make it play whatever it says on the label. Just like a VHS tape, see? Same same.

The thing with tape was that it described the actual medium inside the casing, all the way back to the time before the tape itself came in the casing and was just loose on a spool. This would have been state of the art in the 1960's. It's possible that Original Series Star Trek foresaw the possibility of solid state-ish storage with no tape reels inside, but probably not. (Their computers also exhibit a distressing lack of displays, so I'm not sure the producers were too good at being prescient.) And for what it's worth, I do know a few oldsters who now call the various small card based flash media formats "memory chips," which I guess is pretty close to accurate. TnG did this too with their "isolinear chips," whatever the hell those were supposed to be made of.

Anyway, we do have a limited selection of "phones" without the phone feature, e.g. things like the iPod Touch which was basically an early-gen iPhone with the phone cut out. Nobody could really decide what to call these, with the closest thing to a standard being "pocket media players," which turns into the rather non-melodious "PMP." (With this I guess we missed the chance to call wi-fi enabled variants "pocket internet media players," and therefore have the opportunity to label these "PIMPs," which is obviously much cooler.)

USB-A to A cables aren’t common

I believe USB A-to-A cables actually violate the USB spec and should not in fact ever exist. They definitely should not exist as a straight-through cable (although obviously they still do in reality) without any active electronics in the middle. Male A plugs are solely for connecting to a host device, and the entire purpose of the spectrum of B plugs in their various guises is specifically to make the other end of the cable that goes into the endpoint device different. The point is that you are not supposed to be able to directly connect two hosts together like that.

A straight through dumb A-to-A cable would connect the +5v pin from the host device directly to the +5v pin on the device on the other end of the cable. If you did this between two host devices (i.e. two computers) it is certainly possible that Bad Things would happen if the designers of both devices did not account for this type of stupidity. The only way one of these can be valid according to the spec is to omit the power pins entirely.

That said, I have a particular flashlight that came with exactly one of these naughty cables: A straight through male USB A-to-A cable with no smarts in it whatsoever. The flashlight charges via a USB-A port which is exceptionally bizarre, and I suspect the reason it does so is because it can also act as a power bank and the manufacturer was too cheap to include a type C or micro B or whatever port for input and a separate type A port for output. But now I'm stuck having to use the moronic cable it came with (which is also only like 14" long) without much hope of ever finding an alternative or replacement...

Well, okay. In that case, definitely fuck 'em.

I was just making a hot dog joke, man. We can grind up the shareholders first.

The ancillary equipment and infrastructure for a railroad influences things quite a bit as well. If you just need to privately move things from A to B, it is "theoretically" cheaper to lay rails than build a road of equivalent capability. But a locomotive and cars plus a railyard and a turntable and sidings and switches and all the other stuff you'll need to run trains effectively is going to cost a lot more than just getting a box truck or a even an 18 wheeler and just plonking it on your new road.

A modern freight locomotive will cost you $1.5m to $2m just by itself. Then you need boxcars and all the other stuff, too. Big rigs aren't exactly cheap, either, but you can drive one of those off the lot for less than $250,000.

Connecting your railroad to the rest of the railroad network -- a significant portion of which is privately owned, for an extra special added layer of clusterfuck -- is also a headache. This is trivial for roads, even after you take all of your local government regulations into account. You can make roads go more places more easily.

You are correct that scale is a very important factor for the financial viability of a railroad.

If they were going to bulldoze an inner city neighborhood, it's likely that neighborhood was going to be predominantly black whether they like it or not. The white flight phenomenon predates Costco by a wide margin, and that fuckery already happened decades ago. While there were already inroads to corralling the country's black population in cities around the turn of the century, the ball really got rolling on that in the post-war period following WW2 with redlining, block busting, widespread segregation prior to the civil rights movement, and the white middle class retreating to the then-new suburbs.

They could always grind them up to make into those $1.50 hot dogs.

...I have seven.

Are you sure you're not me?