Great job! Fantastic piece of design - well done! What have you used to design the parts?

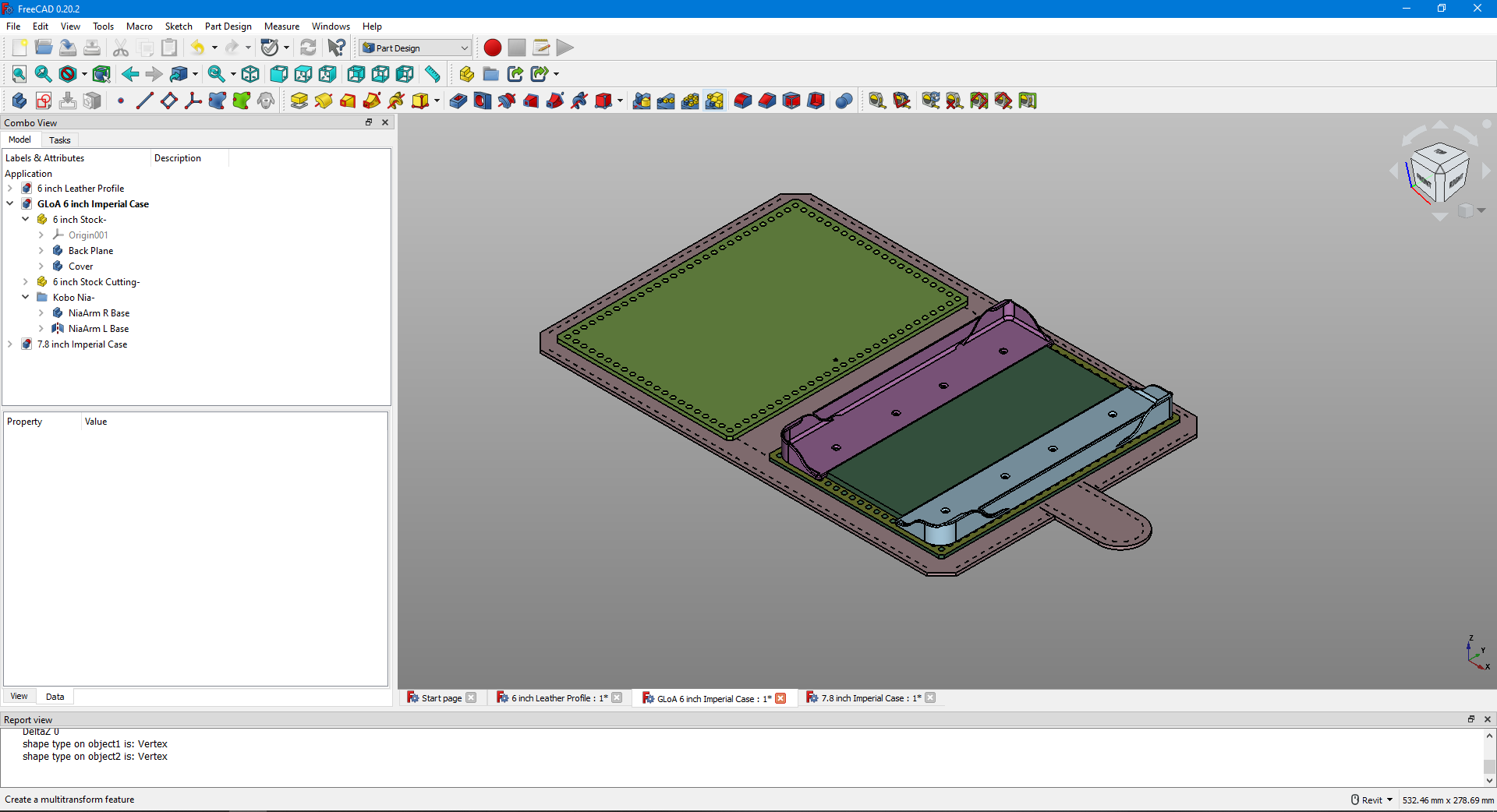

Everything was made in FreeCAD, starting to get good at it since this design took I think 1-2 days versus the 1-2 months the original design took.

I use the Flatten to SVG to get the cutting profiles, while everything else is exported to SVG.

Sweet, I love FreeCAD.

I like it too, but it has issues. These files take a solid minute to load, and I need to disable re-computes if I need to make changes

The delay usually means there is an error somewhere in the file. These are usually things like crossed lines through a pocket or vertices that are not aligned. They can be really difficult to spot. They are usually the result of bad constraints somewhere in a sketch. For instance, if you have constraints related to π, and then edited part of the tree that alters the way π got rounded it can break things in extremely subtle ways that are very hard to spot. You may not even know that π was being used internally to simplify some aspect of your constraints.

Once you know and understand this issue well, it should alter the way you make constraints to a large degree. Like, it is good practice to avoid stacking constraints across a lot sketches by importing geometry. It is better to constrain to the origin and only stack one or two layers on constraints to other geometry. It is best if you avoid constraining anything to a reference that contains infinite numbers like π. The computer's floating point registers are finite and always truncate infinite numbers.

I find it is usually faster to simply rebuild a part from scratch after I get to the point where I have made several changes in the middle of the tree and errors creep in. It is hard to make yourself do this. I feel like I don't want to "give up" on this thing I've invested so much time in. If you simply view it as a rough draft, the you will often see much faster and more efficient ways to build the part when you have a nearly completed design to work with already.

If I do not plan to share the file, I use the old file to make binders, disconnect them, and often just use these to pad and pocket as needed. It is a hacky way to do it, but it is super fast.

The delay usually means there is an error somewhere in the file

In my case, honestly it's probably the fact that I over use constraints and external geometry, and the complexity of the geometry with Linear Patters, and Polar Patters. Each sketch is based off of the last and any small change will effect the entire design. There is probably a cleaner way to do it, but for now yeah.

wait... these eReader-Cases are able to break??

The pink parts yeah. I've seen their eReader get dropped bashed and thrown around like trash (in the bottom of a bag.

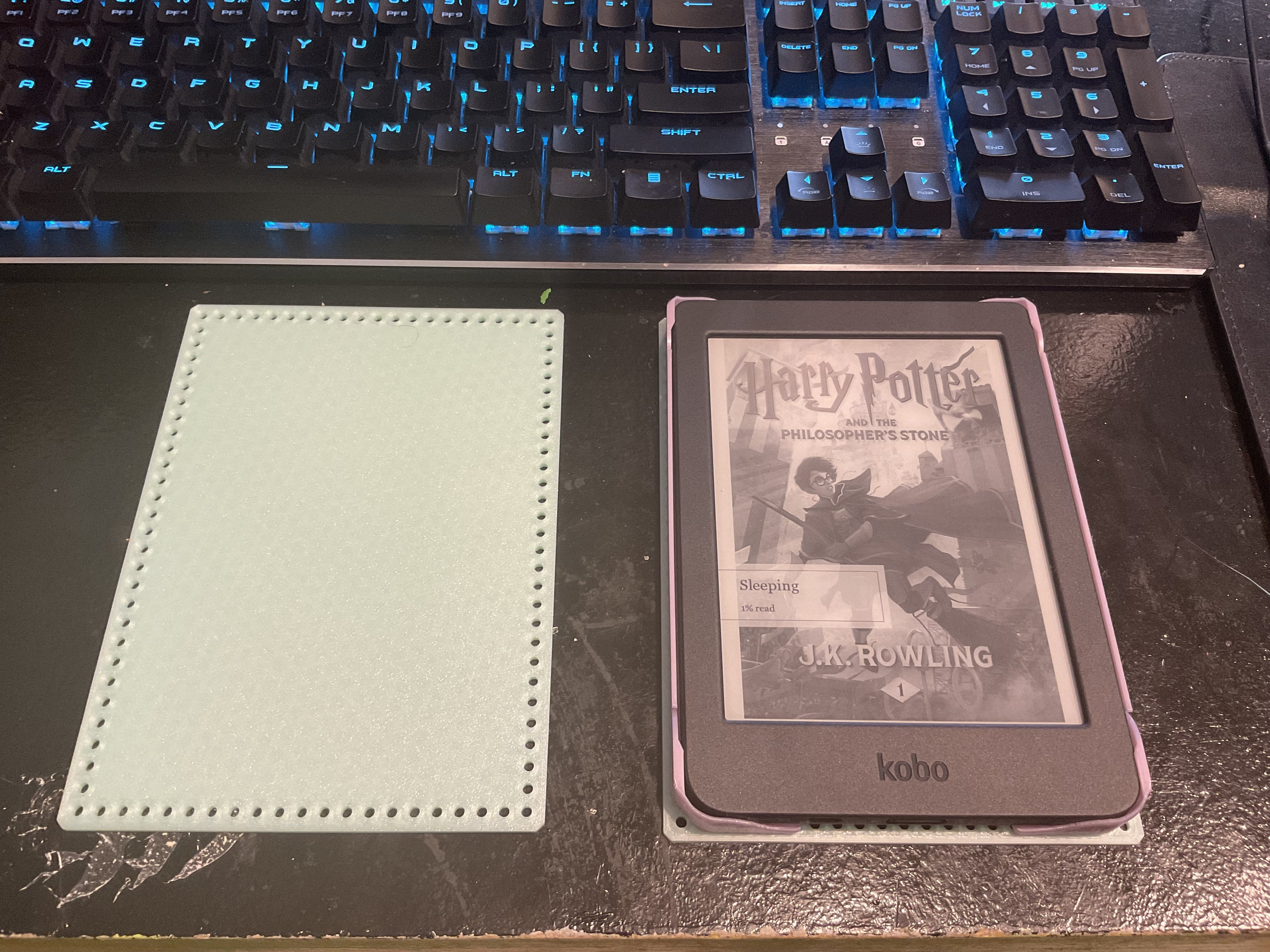

The injection molded cases usually fall apart in about 6 months around the corners, and deteriorate from there. My pink arms are breaking on the layer lines around the corners at the 4 month mark, but they are holding together well regardless. Even then replacement arms are like 4 hours of printing and a few grams of materials.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible